Sewing Machines.

I think its pretty safe to say that most everyone has had a go with one at some point in their life…even if it was only to make a pillow case in middle school Home-Economics class!

The sewing machine has been a staple in homes for over 100 years, and while it may be considered more of a novelty today than the necessity it was back then, they continue to be improved upon and updated with today’s technology…offering more and more bells and whistles than ever before!

Just check out this Brother model, that does everything but fold your clothes, for a cool $14,000.00 price tag.

Now, I love my sewing machines. I have a gorgeous treadle operated 1910 Singer 66, set in its original parlour cabinet and named Helen, after my Great-Grandmother.

how many people can still sew in a power outage in this day and age?

look at that figure! She doesn’t look a day over 87!

and a beautiful vintage 1959 Pfaff 130 Industrial named Pattie-Jean that would sew through concrete if it had the chance (and didn’t have such a limited presser foot clearance!)

My point here is not to show off my machines, but to point out that sewing machines, even though they may be in good-working order, are not all-in-one deals.

Helen is best suited for woven materials, as she is a straight stitch machine, and though she has been kept in great shape, and is all metal mechanics on the inside, she’s not really very equipped for heavy duty fabrics or production sewing.

Patti-Jean, while created to be a workhorse, and better suited for production, (in both speed and durability), has a very limited presser-foot clearance, and lacks the ability to adapt well to modern day attachments (like a walking-foot attacment) where production sewing is concerned.

She is my go-to machine when I’m sewing linings, but has given me lots of trouble with the thickness of multiple layers of vegan leather when sewing my bags. This created a huge time-suck for me, which wasn’t so much of a problem when Wire Peacock was a part-time hobby, and many of my products didn’t use the leather, or used only small pieces as accents.

But over time, my most popular items had proven to be those made entirely (or almost so) from vegan leather, and with the decision to focus on a fully vegan leather product line, and making Wire Peacock a successful full-time business, something was going to have to change.

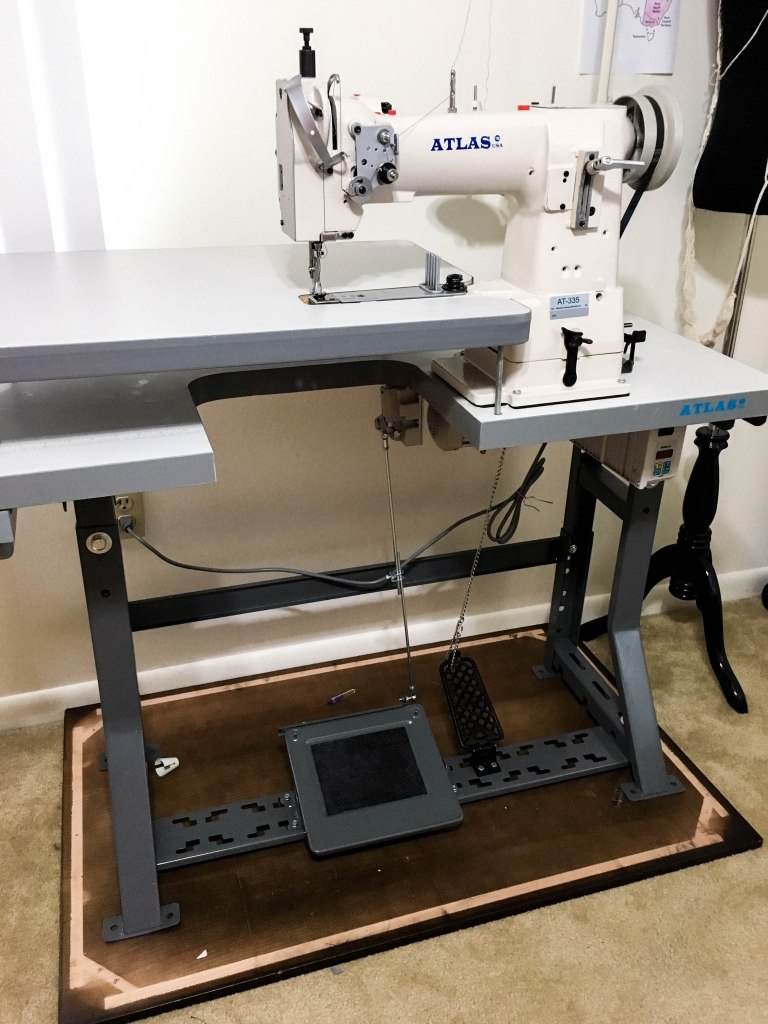

Enter the newest addition to my family; the Atlas 355 Industrial Walking Foot Cylinder Bed.

If your head is spinning just from reading the name of the machine, you’re not alone. It’s a mouthful!

This machine was literally made for my kind of work. The top level of the table is removable, leaving just the cylinder shaped bed (hence ‘cylinder bed’ in the name!) for me to be able to get into quite small areas of the bag when I’m doing the finishing work and detailed stitching.

If you’re familiar with standard home machines, and that presser foot looks funny to you, its because this is a ‘walking-foot’ machine. The outside part of the foot lifts up separately from the inside, ‘walking’ ahead and helping to move the fabric backwards along with the lower feed. This is necessary when using slightly ‘sticky’ fabrics like vinyl and leather (especially with many layers), to keep the fabric moving through the machine at an even pace, and to keep it from sticking to the presser foot.

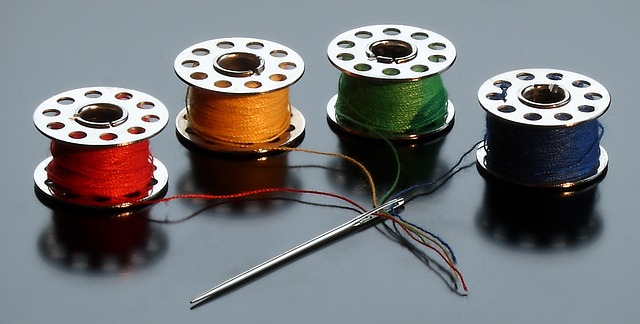

Another difference between the Industrial and a home machine, is its ability to sew with much heavier thread.

Thread this thick would almost certainly mess up the timing or tension on most home machines, but it is necessary when working with fabrics as dense as vegan leather to produce strong seams and even stitches when top-stitching.

forget even attempting to put industrial thread in your home machine bobbin.

Its easy to be blinded by all the features on the newer computerized sewing machines, and they really are great for sewist who do a lot of piece-work and quilting, but in my mind, every single electronic ‘extra’ is just one more thing to go wrong! I prefer simple, mechanical machines, and this industrial baby fits the bill! It goes forward…it goes backward…and that’s really all I need!

plus, I get to make ‘vroom vroom’ noises when I’m using the reverse lever and pretending to down shift.

I recently held a contest in the Wire Peacock VIP Facebook Group to name this new beauty, and the randomly chosen winner was Michaeline’s entry of ‘Stardust’, which as a David Bowie fan, I think is pretty rad!

As a VIP group member, Michaeline was able to participate in the exclusive contest, and won a $25 credit toward her next Wire Peacock purchase! Make sure to click the link above and join the VIP group so you don’t miss out on the next contest! You might just be the next winner!

I hope you all are having a great week! Keep your eyes open for my first ‘Friday Find’ post at the end of this week! Each Friday I’ll be sharing one of my favorite artist or artisans with you, and telling you what I love most about what they do and create!

But for now, help me welcome Stardust to the fleet, and leave a comment below to let me know what you think of her! She’s destined to help me create some pretty spectacular bags, and I can’t wait to share them with you all!

[ Smiles ] A sewing machine that works well is great to have.

As a matter of fact, most households have at least one sewing machine.

LikeLike

I hope they do! It’s such a useful skill to have!

LikeLiked by 1 person

Love the name of your 1959 model! I know exactly who Pattie-Jean is named for!!

LikeLike

Well, they were born in the same year, so it just seemed like a name that was meant to be! 😉

LikeLike

Those machines are lovely, I’ve an old singer from 1915 and while it’s really something special it’s not the most practical. You’re new machine looks so powerful!

LikeLike

It is! It has a servo motor, so I can adjust the speed. I put it on its highest setting when I first got it so that I would know how fast I could sew…I don’t know how anyone could possibly sew that quickly! Lol but it’s good to know that if I ever accidentally gain the superpower of ‘super speed’, the atlas will keep up! 😂

LikeLiked by 1 person